Quality

LEADING-EDGE RESEARCH AND DEVELOPMENT

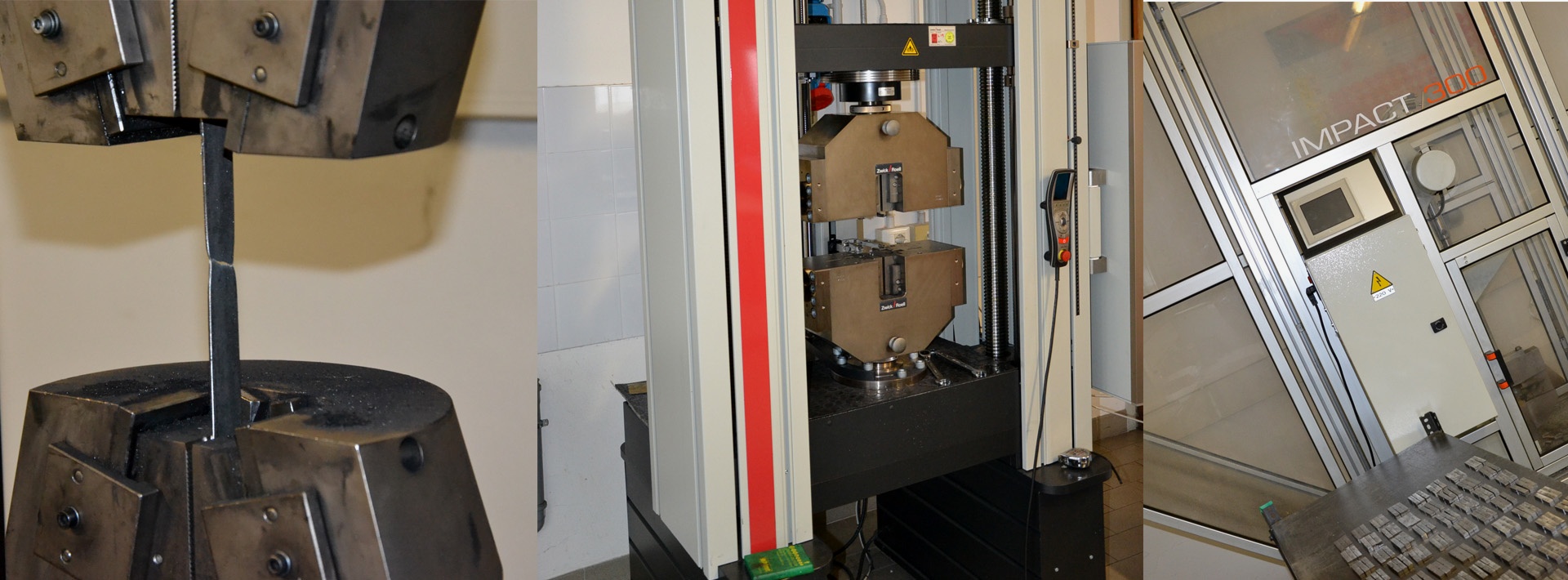

Padana Tubi has a laboratory outfitted with leading-edge equipment and is able to perform tensile and impact-strength tests, chemical analyses and microscopic examinations on all carbon steel and stainless steel products.

The purpose of the tests is to examine the metallurgical characteristics of the materials and conform to the requirements of the following product standards: EN 10219-1, EN 10305-5 (Carbon steels), EN 10217-7 and EN 10296-2 (Stainless steels)

Our in-house laboratory is able to perform:

• tensile tests in accordance with EN ISO 6892-1, where a test-piece of a given size is subjected to increasing tensile stress in one direction until it breaks. This test determines elongation, tensile strength and yield strength, characteristics that indicate the quality of the steel and provide an indication as to the static deformation capacity of the material.

• impact strength tests in accordance with EN ISO 148-1, where a weight (pendulum) is dropped from a set height onto a parallelepiped-shaped test-piece, both ends of which rest on supports. This test measures the toughness of the steel, i.e. its ability to absorb energy before fracturing.

The trend of the impact strength value is affected by temperature and is directly proportional to temperature lowering.

• chemical analyses; samples of metal are analyzed using a mass spectrometer, which establishes the percentages of the elements in the alloy. These product analyses then allow the weldability index of the steel to be calculated.

• microscopic analyses to assess the structure of the steels and the tube welding process.

Non-Destructive Tests are performed on each of the production lines using the Eddy-current method with dog-bone coils for checking welds (EN 10893-2), while circular coils for testing hydraulic leaktightness (EN 10893-1) are used on the lines that produce “PED” Stainless steel tubes.